Although starting your own private label brand might seem exciting at first, it becomes daunting when you have to navigate through the countless options of manufacturers; it feels as if you have migrated to a new country without ever having a chance to learn their language and culture.

Table of Contents

ToggleEven if you are well-known or a new beginner in the industry, you still would have heard about common associated terms such as MOQs, Lead Times, and Bulk ordering.

MOQs or Minimum Order Quantities are the ultimate scope of this blog. Although I wish I could go on a bit about other terminology as well but with time constraints it is best for you and I, if we were to be stuck with MOQs today.

Without wasting any more time, let’s understand what MOQs are. Why do they even matter? And why is it absolutely crucial for business aspirants to understand the factors affecting minimum ordered quantities?

The Core Essence of MOQ Definition in Manufacturing

In the world of private label clothing, MOQs plays a rudimentary role in determining how brands and manufacturers can effectively work together toward a sustainable yet a profitable exchange.

For anyone involved in the fashion industry, regardless if you’re a beginner or an established retailer, understanding MOQs or minimum order quantities is essential for planning, production and even for cost management to ensure a successful tenure of your business.

Let us first begin with the definition of MOQ and why it matters so much!

What Exactly is a MOQ?

Minimum Order Quantity means the lowest possible number of pieces a vendor or manufacturer is willing to make in a single production run. MOQs vary depending on several factors such as Manufacturers themselves[Link to USA vs overseas clothing manufacturers Blog], fabric material, and the complexity of designs.

If a manufacturer says they will provide MOQ of 500 pieces then that basically means they can still be profitable even if they have to run a complete productional cycle and understanding this can help you negotiate for better priced goods.

Why Does MOQ Matter?

Understanding why manufacturers set MOQs is a key to successful patronage, as it’s not about making things difficult for business aspirants; rather, it is deeply ingrained in economics and operational realities of manufacturing.

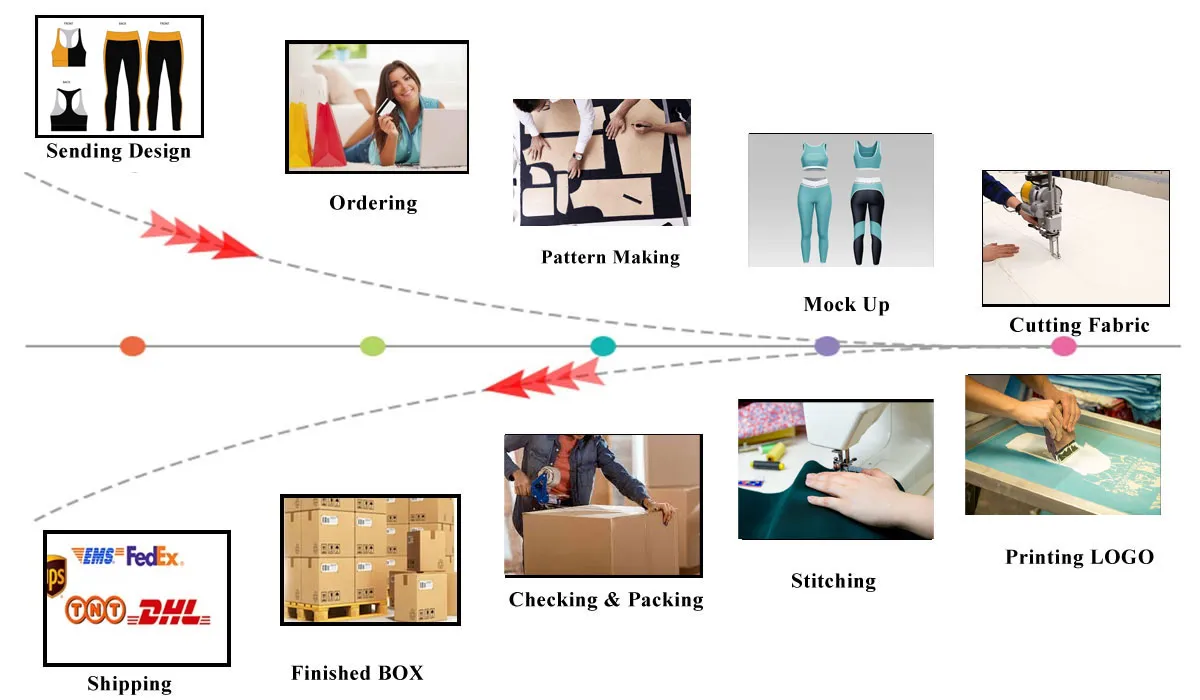

Let’s say you are working with a factory to have your custom activewear made; then each production cycle would involve setup time, material handling, quality checks, and even administrative overhead; this makes production of a very small number of goods costly per unit.

Since any sensible person would want to stay away from expensive clothes sourcing, this is why manufacturers set specific MOQs to ensure they remain in profit by producing more goods in a single production run to for more affordable per unit pricings.

If you are still confused about “why do manufacturers set MOQs“, then I suggest you put extra attention to the next segment of this article to get a better understanding.

Number of Factors Affecting MOQs

There are a number of elements that directly influence the MOQs model and understanding these can help you navigate your way around budget friendly production as they equip you with enough knowledge to know from where and how manufacturers add up costs that leads to higher final costs for making your clothes.

Economics of Production:

One of the main reasons for setting MOQs is to achieve better economies on goods, as producing larger order quantities can reduce the cost per unit because fixed costs such as initial setup, labour, and machinery utilization are spread more evenly through greater numbers of goods.

Whereas if you opt for low number production then it would be very expensive because of uneven distribution of fixed cost factors.

Material Sourcing:

Fabric suppliers often, if not all the time, also have their own MOQs. For instance, a fabric mill might only sell material by a bolt (“It basically means a roll of fabric”) which could be enough for hundreds or perhaps thousands of clothes.

Suppose if a manufacturer has to purchase an entire roll of fabric then they also need to produce sufficient numbers of goods to make effective costing items. Now, imagine if you request them to make you 10 pairs of pants, and then it would be their utmost right to decline your request as it would shatter their manufacturing facility.

Manufacturing Efficiency:

Running a production line involves several initial setups, such as Machinery Configuration and its consecutive calibrations, along with the adjustment of coordinating labor. These setups incur costs that remain the same regardless of the numbers produced. It makes sense to make a larger batch compared to the smaller quantities ordered.

For instance, if you want to have a set of modern T-shirts manufactured and your selected vendors present 100$ setup fees, then it would make sense to have a higher number of products manufactured with the same setup fees as compared to lower numbers.

- Take a look at this short table to get a thorough understanding of “Manufacturing Efficiency”.

| High Number Order | Low Number Order | |

|---|---|---|

| Setup Cost | $100 | $100 |

| Production Cost | $500 | $200 |

| Net Cost | $600 | $300 |

If you take some time and think about this table then you would come to understand that having a high numbered order meant only 16.67% setup cost as compared to 33.33% setup cost for low numbered order. It’s almost double the price!

Inventory and Storage:

Manufacturers also consider the cost of raw material and product warehousing, as if a maker accepts a smaller order, and they might need to rent out a separate warehouse for storage, even if they didn’t need it all. This also increases the overall costs of low MOQs.

Quality Compromises:

A low MOQ can significantly impact the quality of goods manufactured, as smaller runs may lead to increased variability in production runs and potentially lower consistency in the final product. Effectively making expensive MOQs for small businesses.

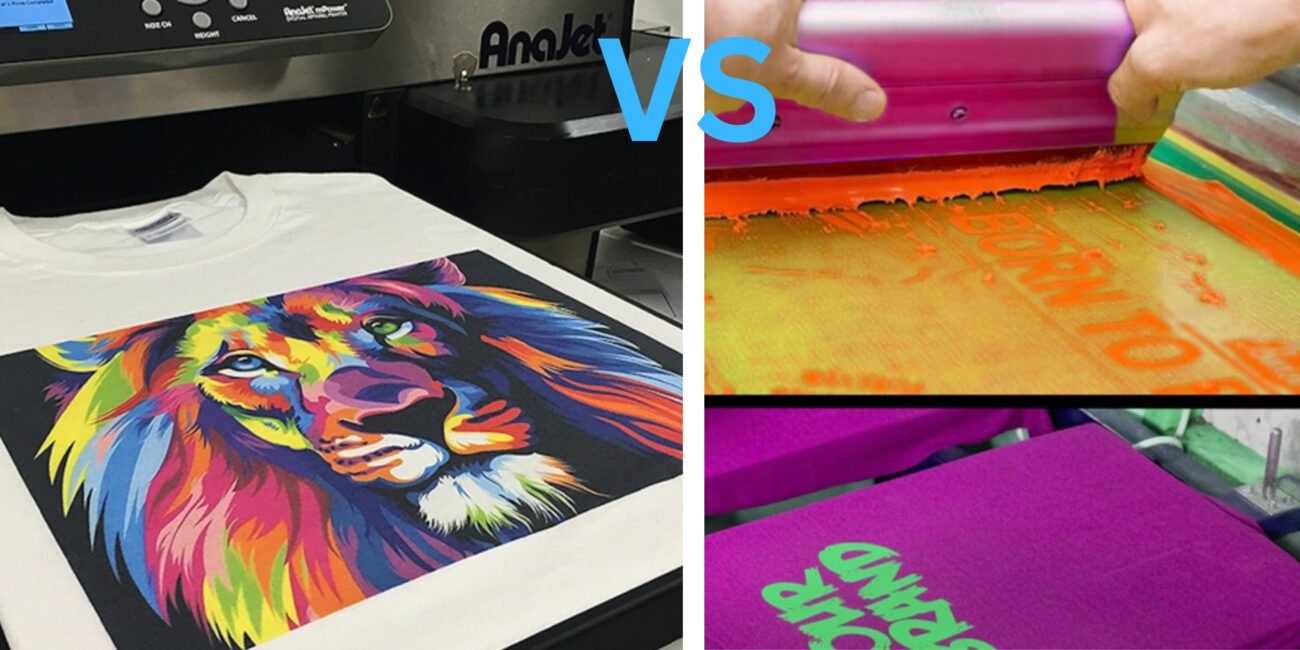

Customization Complexity and Labor:

Highly personalized products that typically involve more intricate designs and details, as well as non-standard manufacturing methods, often require specialized labor and longer production times.

These added complexities increase the other factors of production, such as labour salaries, and machinery optimizations that lead to higher costs per unit. To maintain profitability, many manufacturers only produce highly customized items in large batches to offset these increased associated costs.

Why Manufacturers Set MOQs

Across the globe, you will find that setting Minimum Order Quantities is a common way of doing business for many manufacturers and there are some fundamental reasons for why they do so. Basically, having these minimum standards helps factories stay up and running.

It allows them to plan their production efficiently and make sure that each batch they produce is worth the effort for both machinery setup and staff’s time.

When manufacturers can work this way, they can offer better prices for each item because they’re producing a certain amount at once. In simple terms, MOQs help manufacturers stay in business and offer manufacturing in a way that can lead to more affordable costs for each product you order.

Looking For MOQ Accepted Manufacturer?

Partner with us to bring your custom Sportswear designs to life! As a trusted private label Clothing Manufacturer, we offer top-quality fabrics, expert craftsmanship, and personalized solutions to match your brand’s style.

Covering Initial Investment and Operational Expenses:

Manufacturers have significant upfront investment requirements in their facilities regarding machinery and technology, and this becomes more apparent when we talk about B2B manufacturers.

Setting MOQs helps them to ensure each production generates enough revenue to cover initial capital and the continuous cost of running their business. Without sufficient order volumes, there could be risks of operating at a loss.

Ensuring Profitability and Sustainable Production:

Manufacturers operate on profit margins to sustain their business and future growth. Producing very small quantities might not yield enough profit per unit to make production and associated staff time worthwhile.

MOQs help them achieve economically viable production runs with sufficient volumes to generate healthy profit margins. This ensures the long-term sustainability of their manufacturing operation.

Minimizing Waste and Optimizing Resources:

Although it might not seem much, producing larger batches can sometimes lead to better material utilization with minimum wastage than small batch production. Setting up machinery and its associated calibrations often results in some initial waste.

By running a larger batch of production, this initial waste becomes negligible and spreads across more units and effectively reduces the overall waste percentage. Efficient production manufacturers also optimize the use of labor, energy, and other resources, contributing to cost-effectiveness.

How to Reduce MOQs: Tips for New Private Label Brands

It is never easy to run a business, especially a clothing business that changes overnight, where one thing might become exceedingly popular whereas another becomes obsolete and by this point i am sure you would be asking yourself “alright i got to know about how manufacturers decide MOQs ranges but how can i reduce the MOQs price for my brand”?

Well as a business owner myself, if you can understand the core reasons of MOQs planning and then make a strategic work around it then you can easily navigate through the world of private label product sourcing and become successful in no time! You take a look at below mentioned points to get a better grip on managing MOQs pricings.

Understanding Your Own Demand and Forecasting:

Before approaching any manufacturer, you should run a thorough market research to develop realistic sales projections and potential demand for your products. If you sign up for manufacturing demand without even analyzing what your customers want, then your brand will surely be set for failure.

Understanding these factors associated with your brand can help you determine a sensible order quantity that aligns with your business needs and allows you to meet manufacturers that provide adequate MOQs without overstocking your inventory.

Exploring Options for Lower MOQ For Small Businesses:

Although MOQs are often, if not always, firm, due to the manufacturer’s costing plan. There are other flexible options you can explore as well, as higher production doesn’t always mean the exclusivity of quality.

You can try to find smaller manufacturers that offer specialized services and affordable production runs while offering lower MOQs, but be prepared if you go along that side of the manufacturing world, then you should also be ready for inevitable tradeoffs that come with it. Which mainly includes high cost per unit, meaning low net profit for your brand, but honestly speaking, it’s not that bad if you can not afford high capacity manufacturing.

In fact take a look at the table below to get a thorough understanding about the benefits and setbacks of large and small vendors. This will definitely help you choose the best for your brand.

High MOQs Manufacturer:

Often best suited for those who are running a profitable business or even a company that works on contracts. High MOQs generally mean less cost per piece, meaning more profits on product sales.

| BENEFITS | SETBACKS |

|---|---|

| Lower Per-Unit Costs | Higher Upfront Costs |

| Better Negotiating Power | Risk of Excess Inventory |

| Consistency in Production | Limited Flexibility |

You can clearly see that it is beneficial in longer runs. High Capacity Manufacturing also has its own sets of flaws, one of the major alarming concerns has to be excess inventory and limited flexibility, meaning you can not go around experimenting in each trend and this might prove to be detrimental for your business.

- Low MOQs Manufacturer: Often best suited for those who are wanting to start a business or already have a small group of customer base. Low MOQs mean more cost per piece, meaning less profits margins on product sales.

| BENEFITS | SETBACKS |

|---|---|

| Lower Risk | Higher Per-Unit Costs |

| Greater Flexibility | Limited Negotiating Power |

| Reduced Storage Costs | Potential for Inconsistencies |

You can now see a clear image, choosing a low MOQs manufacturer for your brand will definitely be cost saving in the beginning but it will also lead to minimal relationships with manufacturers and many inconsistencies. Essentially, minimum chances for growth in the near future.

If you are not sure about which side of the manufacturing world you should opt for, then let me tell you about staged and consolidating productions.

Stage production basically means you negotiate with the manufacturer for the first initial order and make an agreement that if your clothes sell well then you would place a larger MOQ order and on other hands consolidating production basically means pooling different brand’s manufacturing needs and organize them in such way that it can be produce via high capacity production run. These are some of the methods I have opted for in my business as well.

This strategy essentially eliminates the setbacks of production and allows for a profitable business regime.

Building Strong Relationships with Manufacturers:

One of the significant factors that contributes to negotiability in MOQ is a strong and positive relationship with the manufacturer. So it is advisable to be as open and transparent about current business goals and future plans as possible and if you remain consistent throughout with order volume and reliability then chances are, even manufacturers themselves would be open about negotiability, which can result in lower per unit costs and effectively means more profit margins for you!

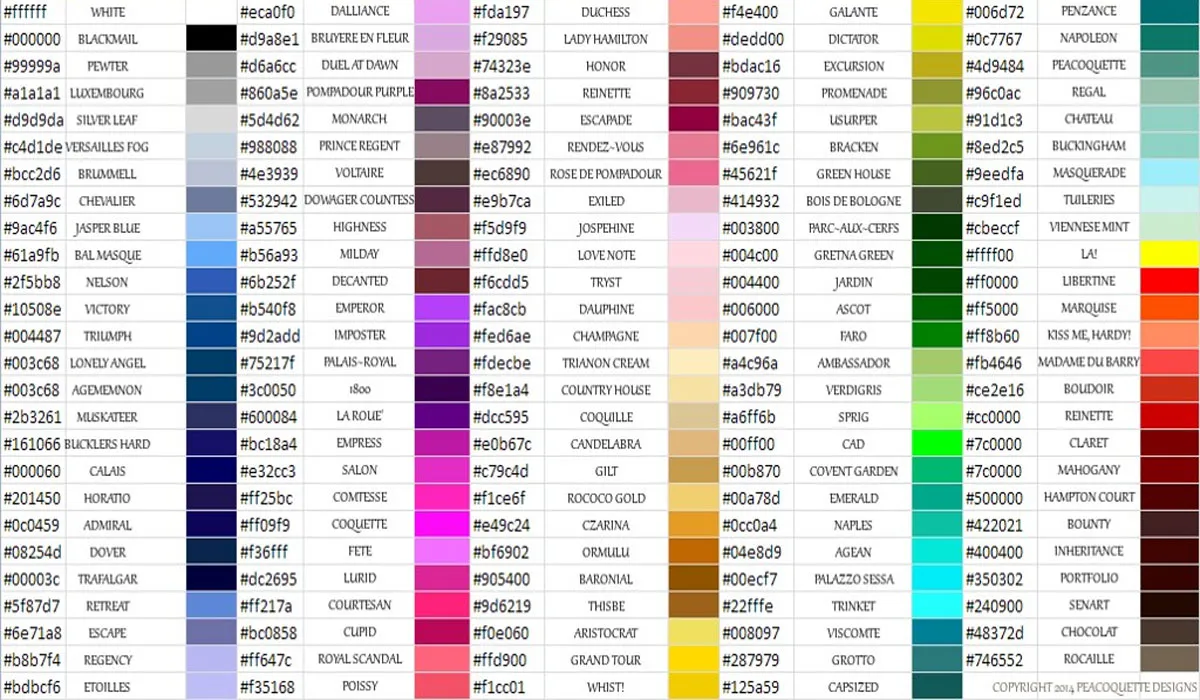

Strategically Planning Your Initial Product Launch:

If you are a new business owner, then consider fewer variations in sizes, colors, and features for your initial launch, as this can help you meet MOQs for a smaller number of SKUs more easily. And once your brand gains enough traction and better understanding of the intended audience’s demands then you can gradually expand your range to offer a plentiful variety in your clothing lineup.

NOTE: You may have noticed a unique word here. SKU or “Stock keeping unit”, It basically means the units or clothes in this scenario, that keeps the inventory full. It helps sellers navigate their inventory.

The perfect manufacturer for your brand or vision has to be the one, who provides minimal MOQs with affordable prices, although it is challenging but not impossible to find such vendors that cater to new business with the same vigour as they do with well known players in industry. I really recommend checking this manufacturer out as they not only provide minimal MOQs but also market-competitive quality.

Click Here: Private Label Clothing Manufacturer

Conclusions

Lastly, choosing a perfect manufacturer for your clothing needs is a time-consuming and challenging task. Understanding the basic know-how of the field can empower you to make informed choices for your brand, as not every manufacturer’s MOQ range might suit your goals.

However, if you take some time and conduct a thorough research on the market and effective solution-providing manufacturers about their way of scaling per-unit costs, then you can strategize your way into high-quality private-labelled clothes sourcing while keeping minimal order quantities.

FAQs

1) What are typical MOQs in the clothing industry?

MOQs can vary greatly as they directly depend on the manufacturer. For example, a high-capacity manufacturer will have 500-1000 minimum order quantities, and low-capacity manufacturers might have 100-200 minimum order quantities.

2) Why are low MOQs considered significant for new business?

Having low MOQs can be beneficial in a number of ways. It requires a low initial investment and less risk of overstocking, which essentially allows endless opportunities for business.

3) How do I calculate what MOQ I can realistically handle?

To calculate your optimum MOQs realistically, consider your budget, storage capacity, projected sales, and risks associated with unsold inventory.