Thinking about starting your own baseball hat business, but are not sure how that even works? Then you are in the right place. Before getting into the business side, you need to understand how baseball hats are made and understanding various parts of a baseball hat can equip you with the necessary knowledge to make custom hats that stand out from the competition.

Table of Contents

ToggleNow, not all baseball caps are manufactured using the same procedure, as differences in various parts add up to the final look and functionality of the cap. But let’s see how a cap is typically manufactured before discussing baseball cap parts.

Introduction: How is a Cap Manufactured?

Cap manufacturers have been practising making hats for decades now, and you would be surprised as to why such a simple fabric piece took so long to perfect. Before the dawn of modern fashion, there was no distinction between different types of headwear, and it often confused vendors, but with a modern outlook, a streamlined production process has finally been applied.

Here’s what goes into cap manufacturing:

Initial Design:

Before anything else, the style, Shape and Dimensions of a cap are decided and pondered over. You can either do this with pen and paper or through digital drawing software. Later, these designs are perfectly patterned, but not in one go. Different parts are drafted into dedicated sections, as this allows modifications even at later stages.

Fabric Selection:

After patterns have been created, the next step is the fabric selection and cutting. Both required tedious work, as you may already know, not all fabrics are the same, and similarly, if the material is not sliced skillfully, then it can end in a disaster.

Common materials such as cotton, polyester and blends thereof are sliced using either die-cutting machines for larger batches and laser or manual cutting for complex designs and smaller batches.

Cut pieces include:

- 5 or 6 fabric panels for the crown.

- 1 or 2 pieces for the brim.

- Sweatband.

Customizations:

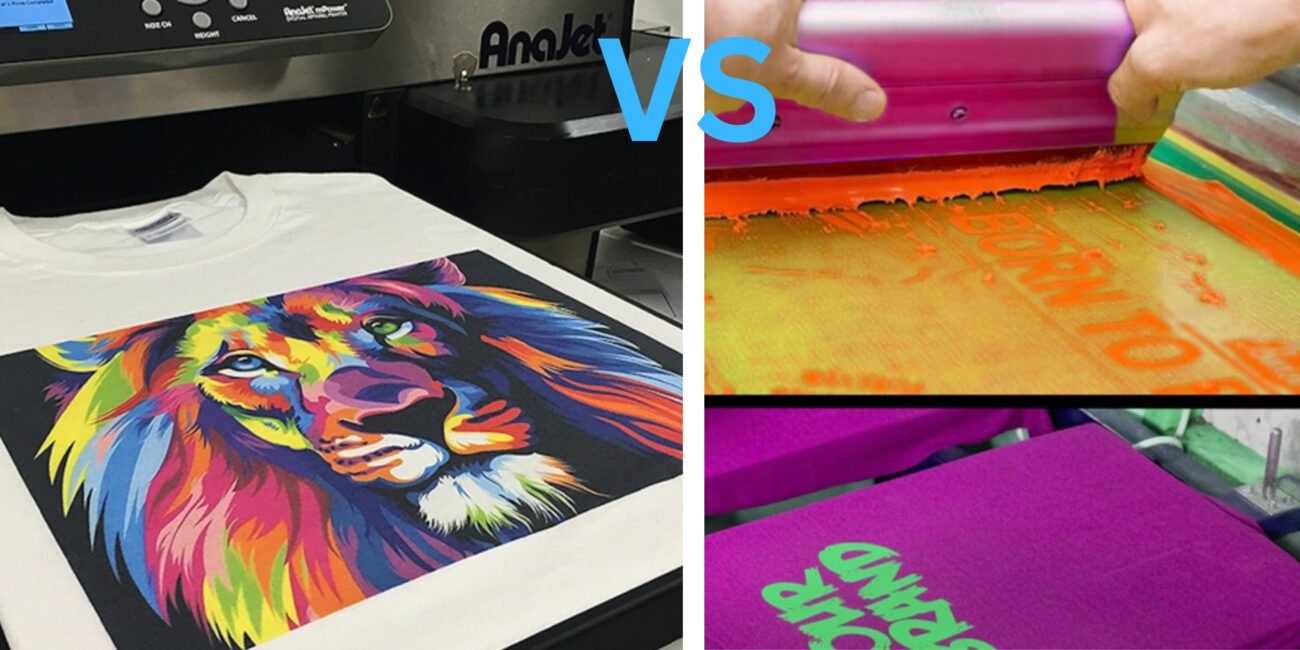

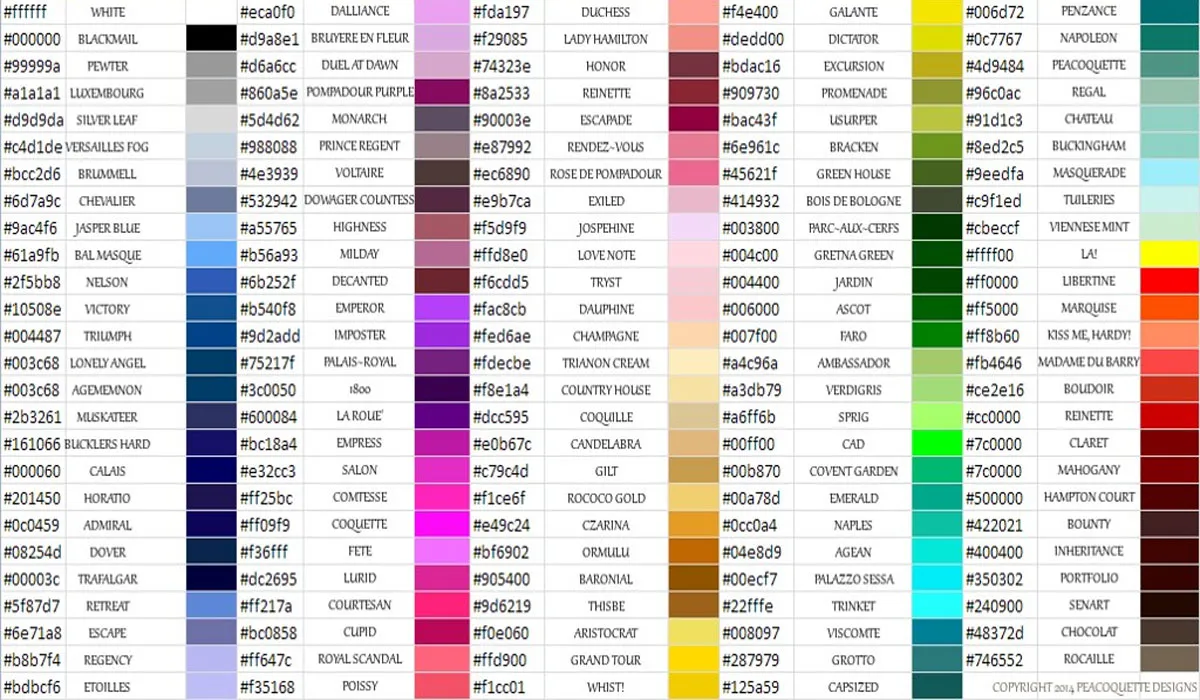

If all-over graphics style is not your cup of tea, then this is where logos, text and even smaller graphics are added onto those cut pieces using embroidery and printing options such as screen printing and heat transfers.

Valuable Info: Remember I said, how Cap’s design changes their manufacturing strategy. If all-over graphics design was your approach, then you would have to pre-print fabrics before slicing them up; otherwise, can you imagine stuffing a formed cap or even cutting pieces into machines?

Crown & Brim Assembly:

This part requires utmost care, because imagine you got everything right and then opted for manufacturers without a proper skillset and relevant experiences, chances are they will mess up your caps. This is why having the right cap manufacturers on your side is really significant, with your input and their expertise. You can be assured of quality stitching and buckram reinforcements for structured caps.

When the Crown is being stitched, a button coated with the same fabric type is often added on top for further security. Afterwards, the brim is stitched according to the design plan of the cap. If it’s more of a visor, then it’s usually just stitched at the front, but if it has a curved brim, then it goes around the entire crown.

Inner Linings:

When the cap is mostly prepared, inner linings are sewn on for various reasons such as comfort, moisture-wicking, and even labelling. At this step, if plausible, manufacturers also add a sweatband that traps sweat into the cap, giving you that fresh wearing experience all day long.

Closure system (If Not Fitted Cap):

Baseball caps are mostly adjustable, which allows for personalised wearing experiences. Owing to such significant functionality, there are multiple choices such as snapback closure, Velcro and even elastic bands. This step is always last.

Quality Control:

Lastly, finishing touches and quality controls are organised to make sure each cap turns out well enough according to the standard.

During this stage:

- Threads are trimmed.

- Caps are shaped by steaming.

- Final brand labels are added.

Create Your Custom Hats!

PLCM are excellent in their craft and have been known around the fashion industry for their quiet designs and lead times. We understand what it takes to make a good hat, This is why we provide MOQs of just 50 pcs to help startups in their business venture.

6 Different Parts of a Baseball Hat You Should Know!

If you had read carefully, then I am pretty sure you must have gotten all the main parts of the cap, but if not, then let us also discuss them separately. Just remember one thing: cap styles are formed when one or more of these parts are changed or formed differently.

1- Crown:

The crown is the heart of every cap; it is the top portion made using either 5 or 6 panel fabrics and sits right on the head. The crown gives the cap its overall shape and silhouette. Depending upon the types, crowns can either be structured or unstructured, but when talking about baseball caps specifically, crowns are always structured, but sometimes buckram on the front panels is included, and sometimes it is not.

What does structured crown vs non-structured crown mean?

If a cap’s crown is made using firm materials, then it will uphold its structure, whereas softer materials would lead to a relaxed crown, which is often called a non-structured crown as well. Crown Style depicts the fashion potential of caps, as a stiffer design means a polished and sophisticated appearance, whereas a crown that lacks rigidity means a relaxed and more casual look.

2- Brim:

These are some of the most important parts of a baseball cap. If not for it, then baseball caps probably wouldn’t even be this popular. Brim adds that we all need well-needed functionality in baseball caps, we all love and adore. This frontal covering comes in two types.

I’m sure you must have heard of visor and brim, well, both of them are generally the same thing, but since you are reading this blog, most likely for informed knowledge.

Consider this, Brim circles the entire base of the crown and can vary in size, offering protection against environmental elements such as dust and stones, whereas the visor is projected outwards to shield eyes from sunlight.

However, it is difficult to say which one is better, as both serve one aim and vary almost negligibly. But go for Visors if you want hair-friendly caps, whereas brims are for sweat management and style versatility.

3- Sweatband:

Sweatbands are not always included in baseball caps, but are very useful for sports lovers. Sweatband is usually made with moisture-wicking materials like polyester and is placed around the inner circular edge of the crown.

When worn, it absorbs sweat and stops it from getting into your eyes during high-impact activities. Sweatbands, if made with softer material, can also act as a comfortable layer between the cap and your head. So, if comfort and sweat management are your concerns, then go for baseball caps with sweatbands.

4- Button & Visible stitching:

Have you seen those buttons on top of the crown? Many of us might think it’s just there for aesthetics, and quite honestly, that’s mostly true, but the button also provides structural integrity to those fabric panels. It is mostly made out of either plastic or rigid fabric and is placed right at the top to hold fabric panels even tightly.

This small detail can significantly add up to hat’s overall design, from simple colored buttons to ornate, branded ones.

Stitching, on the other hand, is purely ornamental and provides absolutely no value to the hat’s structure and durability. And I’m not talking about the actual fabric stitching, it is one of those thread lines you see on the brim of hats. It can be in the same colour, but custom hat manufacturers often include different colored threads to add to the feel of the hat. You can say this visible stitching is more of a fashion thing than anything else.

5- Eyelets:

Unlike buttons and stitchings, eyelets are purely functional and are absolutely a must for caps made with denser and non-breathable fabric. Eyelets are those small openings on the crown, characterised either by metal rings or embossed threadings. They are strategically placed to increase air flow to keep your head warm, especially during warm weather and physical activities.

6- Closure:

A hat’s closure system is necessary. Most baseball caps are made to be adjustable, and different designs aim for different closure systems, but one thing is clear: Without this part, you can’t make modern baseball hats. These closures are necessary for a perfect fit.

- Snapback closures feature a flexible plastic closure that provides a range of sizes.

- Velcro systems offer similar adjustability but are prone to damage.

- Adjustable straps are made either of fabric or leather and come with a sliding buckle for adjusting sizes.

The choice of closure system ensures how well a hat may fit and contributes to the overall style. Remember this: leather strap for a classic look, while snapback closures for a sporty look.

How is a Baseball Cap Different From Other Hats?

Baseball caps are casual, sporty and adjustable, which makes them a popular choice for everyday wear and athletic use. Unlike other hats, such as fedoras, beanies, and even bucket hats, baseball caps are highly versatile and are not specific to one style. Baseball caps are also inherently different due to their structured crown with a flat brim that looks both fashionable and acts as a barrier against sun glare.

Related-Read: Snapback vs Baseball Cap: Which One is Right for You?

How to Create Your Own Baseball Hat With Private Label Clothing Manufacturers?

Have you figured out everything, the designs and fabrics for your baseball hat? Then your next step is to find proper manufacturing partners that provide not just low MOQs but also market-competitive quality products at challenging prices. Chances are, you will mostly fail to find such makers; this is why I decided to tell you about private label clothing manufacturers.

They are couture custom clothing makers and have been in business for years. PLCM works on trade insurance and aims to provide a quick solution for your custom hat designs.

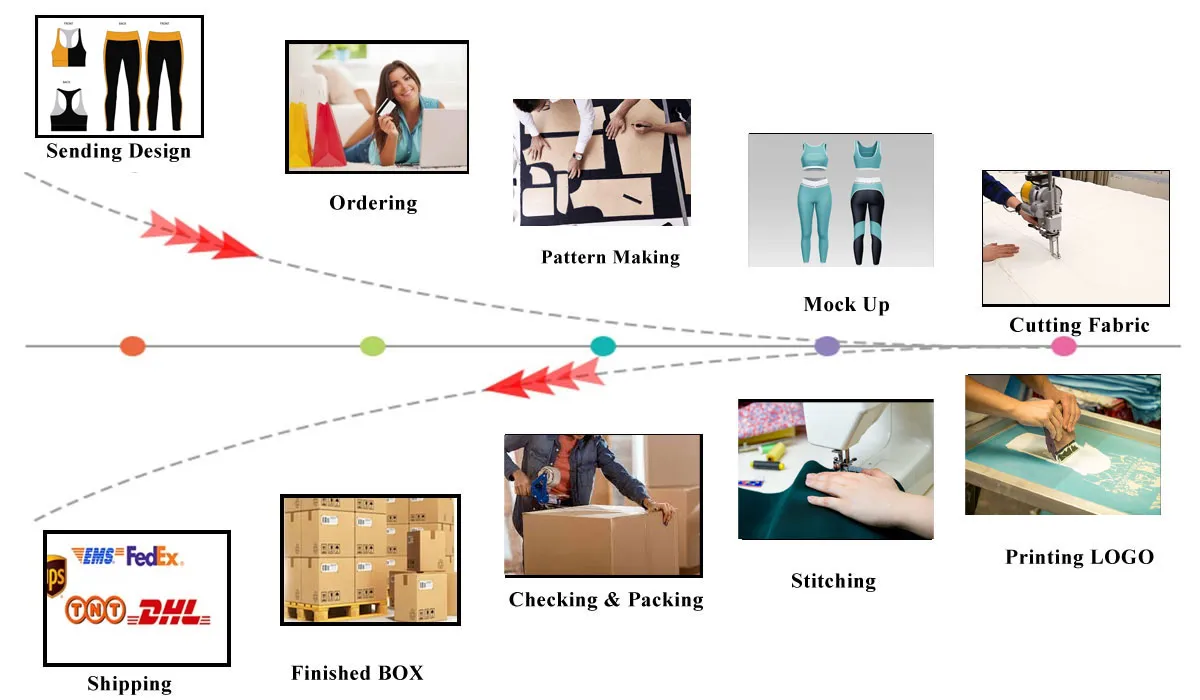

Here’s how they typically process an order:

- After receiving an order, their dedicated support agent will talk to you about your designs and help you make a blueprint based on your requirements.

- Then, the blueprints will be handed over to the graphics team for free-of-charge mockups. This way, you can preview your baseball hats digitally before going further.

- Later comes the fabric’s selection, it’s alright if you are not knowledgeable about them. Just tell PLCM’s experts what you need, and they will guide you through the choices.

- Now, actual pattern making, cutting and assembly will take place in different assorted departments.

- Once your hats are finalised by crafters, they will be pushed to the customisation aisle. Where heat transfers, embroidered logos and even brand labelling will be carried out.

- Now, your order will go through their 20+ screening to ensure each piece is of standard quality.

- Finally, they will be shipped out to you via DHL, UPS and FedEx through C.I.F or F.O.B means.

Quick FAQs

Are there unstructured baseball caps?

Yes! There are unstructured baseball caps, but they are not as unstructured as you may think. These baseball caps lack the reinforced buckram but still maintain that silhouette every baseball cap is known for, and compared to buckram caps, these baseball caps are soft and give that worn-in feel that moulds on your head perfectly.

Which is better, an unstructured crown or a structured crown?

There is no direct answer to this; structured and unstructured crowns both are for different styles. If you are someone who wants a crisp hat with popped graphics, then structured crowns are for you, but otherwise, you can never go wrong with unstructured crowns because of their relaxed fitting and convenience to carry.

Structured crowns are in trend, whereas unstructured crowns are classic as they get.

What are the parts of a baseball hat called?

Depending on the complexity of designs, there can be many parts to a baseball cap, but generally, there are only five main parts of a baseball hat. These are Crown, Brim, Button, Eyelets and Closure systems. Most, if not all, caps are based on these five parts.