Have you been thinking about starting your own private label clothing brand, have even designed products, and are just about to go into production? Then take an immediate halt!. How confident are you about the costing plan? Do you think they are providing more value than others? Or even value at all!

Table of Contents

ToggleSpeaking from my own experiences, as a business owner myself, I always found it extremely tiresome to find manufacturers who are transparent in their production and enumeration plans, but somehow and from somewhere, I would always end up paying more than agreed terms.

Only then did I realize that starting your own brand might not be as difficult as finding the vendors that offer adequate clothing manufacturing pricing.

If you too are concerned about the costing factor for your brand, then follow me till last to get a comprehensive understanding of how manufacturers charge you and what other factors influence the Cost along with solutions to high Cost of private label apparel.

Introduction: Diving into the World of Private Label Clothing

Clothing manufacturing costs are perhaps the ultimate concern of every business person trying to be profitable in 2025. It is quite obvious that investment plans and product-to-price ratio play a crucial part in business operations, meaning if a business aspirant is not aware of these costs and strategies to tackle them, then their business probably wouldn’t go so far.

This is why I believe understanding pricing and how manufacturers break down said costs is mandatory for any brand’s success.

Estimating manufacturing cost can go from 15,000$ to 30,000$, and the worst part is, this pricing projection is for only new brand owners. You can multiply the upper range by x20 to get the amount most big brands spend in about a quarter to meet their manufacturing needs.

Honestly speaking costs depend more on the vendors than products, the more customization and addons you request, the more they will charge you and if you are thinking “My MOQs are low thus meaning low costs” then you would be dead wrong, as typically factories charge their fee over the net Cost required for production, going by that logic ordering a huge number might prove to be more affordable in longer run.

If a brand’s associates are not ready to balance the cost-to-production ratio, then I seriously suggest getting a professional accountant to do it for you. Many, if not all, manufacturers outsourced help to get their factories up and running, too. So why not you as well?

The Core Components of Private Label Clothing Manufacturing Costs

As previously mentioned, Private label clothing cost can be categorized into different aspects, which all influence the final prices and I believe if you are able to rectify even just 1 or 2 aspects of costing then you would see a drastic decrease in pricing.

1) Raw Materials:

The foundational Cost of your clothes, this aspect covers everything that goes into its structural creation.

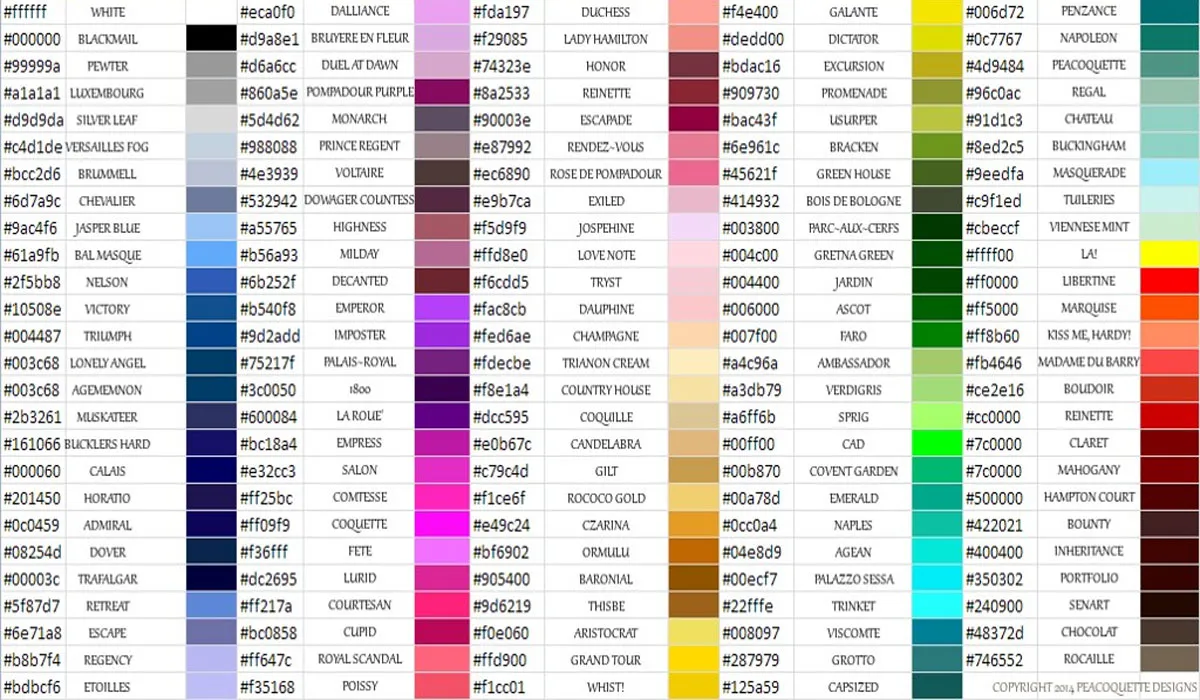

- The Selection of Textile Material is the primary reason for expensive production, as factors like fiber content, its type, and even quality play a significant role in the final price.

For instance, if you are looking to have your T-shirts made with high quality cotton then it will cost 8$ per-unit whereas a T-shirt made out of merino wool would perhaps even be more than 40$ because of the expensiveness of wool.

- Beyond the Fabric Types, other factors that heavily influence cost are trims and accessories. Although they might not sound substantial, these seemingly small details, such as buttons, labels, and suppers, can collectively contribute to the final price.

- Lastly, the origin of material and MOQs determined by vendors will directly impact your initial investment as well as the per-unit Cost. Thorough consideration of each of these material aspects can help you manage cost.

2) Labor Costs:

The labor involved in transforming raw materials into finished sets of clothes is also a substantial cost influence factor.

- This aspect includes the skills required to cut fabric according to the pattern, followed by the actual sewing of fabric into clothes and finishing touches like hemming and ironing.

- Labour costs also vary depending on the country and its standard living wage, as factories in countries like China, Bangladesh, and Pakistan offer lower labor costs for more competitive pricing, but factors like ethical labour practices and quality controls should also be considered to avoid a future sham that might tarnish your brand’s name.

- Complexity of designs also affects costs, as more intricate designs with numerous seams and embellishments will require more skilled labour and time.

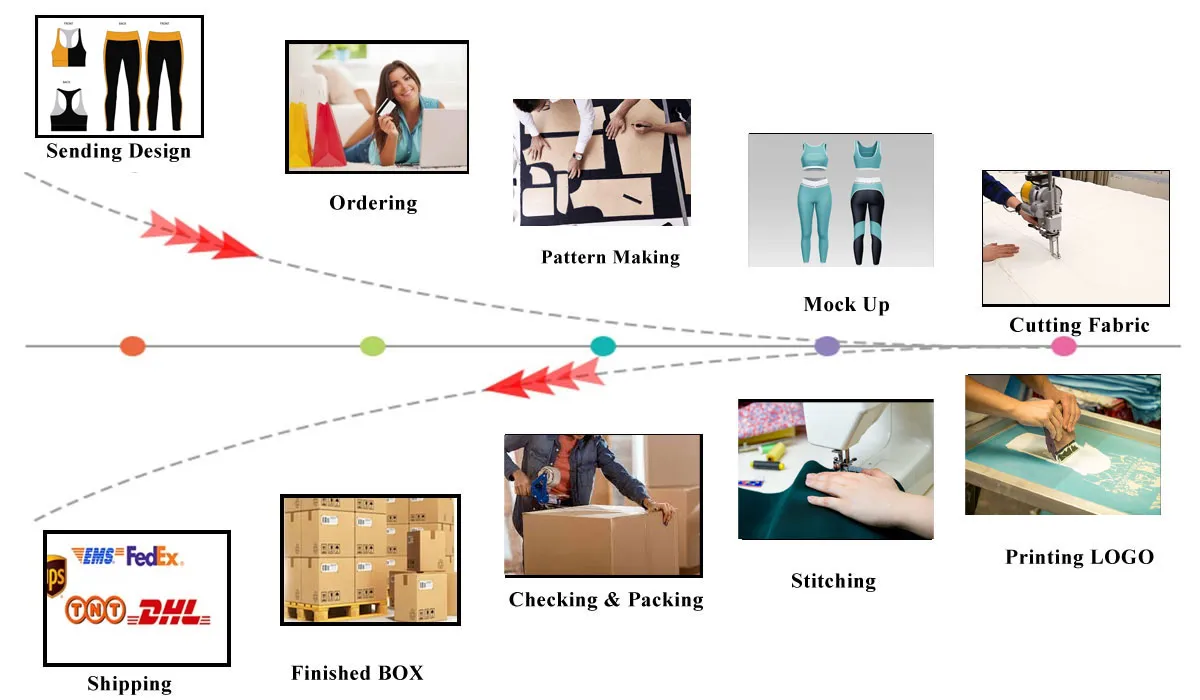

3) Manufacturing Processes:

The actual production process, which includes sampling rates, production runs, and even QC, further influences the final cost. You can think of it as having a direct relation with Cost, as low Quality and Cheap production runs will result in shabby-looking products, while high-standard production will similarly result in high-quality products.

Also, the number of pieces you decide to manufacture significantly affects the per-unit Cost, as large production runs typically lead to a lower per-unit price due to economies of scale, as fixed costs spread more across the whole purchase order.

- Translating your designs into precise patterns is a crucial step in production, but when you start grading designs, it means making the same pattern but in different sizes. This process can directly affect the associated costs.

- Sample production is another essential factor that contributes heavily to cost increment, as throughout the manufacturing process, you have to evaluate various iterations of designs and their associated fitting and quality before full production.

- The number of pieces you decide to have significantly affects the per-unit Cost, as large production runs typically lead to a lower per-unit price due to economical scaling that spreads more costs across.

- Also, if you wish to have strict quality controls throughout the manufacturing process, then it will also add to costs because doing so is extremely important for high-quality clothes.

4) Overhead Costs:

These are the behind-the-scenes factors that add up to costs, although it is a bad practice for many manufacturers to dump their functional costs on us customers. Thus, it directly influences the costs of bulk orders. These hidden prices usually don’t apply to samples.

- Manufacturing facilities have several operational overheads, such as rent of buildings, electricity to run machinery, and water required for washing and finishing of clothes, which are also factored into the final prices they offer to us. Frankly speaking, this leaves a very bad taste in my mouth, but I can’t change the whole clothing industry. Can I?

- Vendors all over the world also add the maintenance and replacement cost of machinery to the final costs, which results in a substantial increase in private label production costs.

- Other factors, such as administrative and staff management, contribute to overall expenses as well.

It is very rare to find such makers that don’t charge you miscellaneous charges, and if you can not find a suitable manufacturer for you, then I suggest you check this manufacturer out.

Click Here: Private Label Clothing Manufacturer

Additional Factors Influencing Manufacturing Costs

Other than the direct Cost influencing aspects, there are multiple external factors that contribute to overall production cost, because as a business owner, you will not just take into account the production cost as it is; for you, the final production cost should include everything that was required to get your order to your location.

You can take a quick look below for a thorough understanding of these so-called “Additional Factors”.

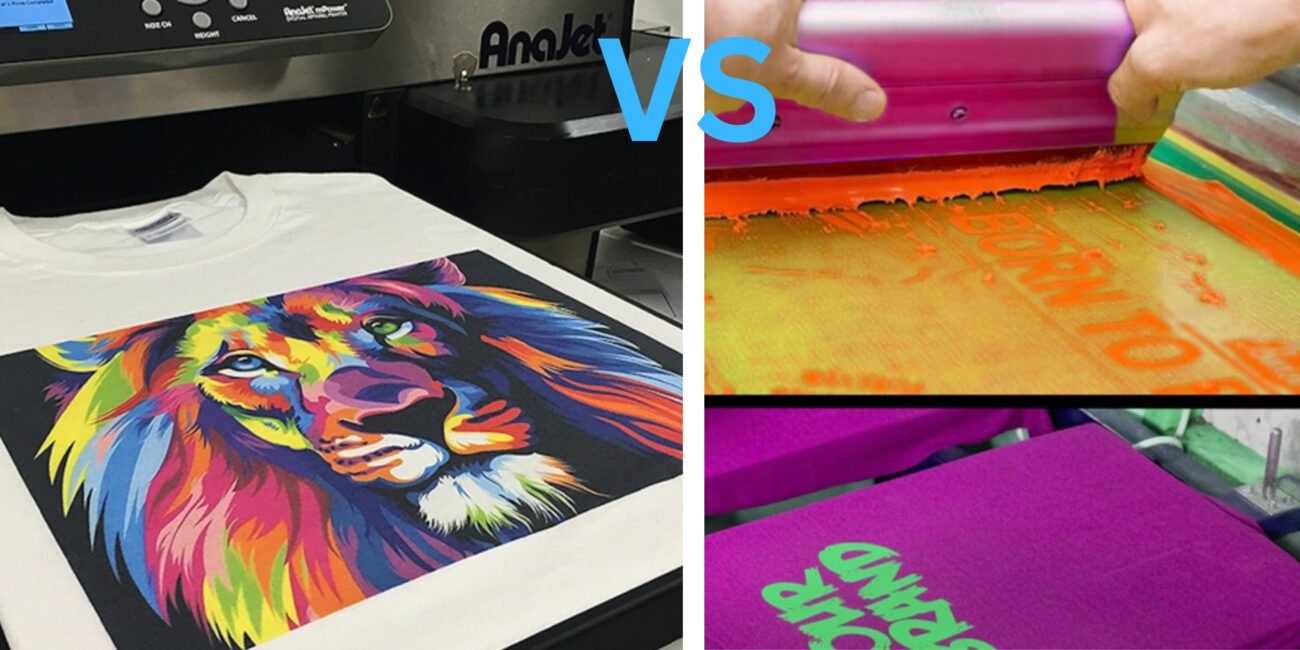

Design Complexity and Customization:

- The more intricate your designs are, the more costly they will be to produce. This factor encompasses not just the structural design but also embellishment, custom prints, and even special packaging requests. Basically, it means the more customization you want to add to your goods, the higher the final asking price will be.

Order Quantity:

- As mentioned earlier, the volume of your order is a key factor that determines final private label clothing pricing, as smaller quantities often come with higher per-unit Cost, whereas larger quantities tend to come with lower per-unit Cost.

Suppose you are someone who sells in a specific season and often requires a huge number of pieces, then going for a larger production number will undoubtedly prove to be the best choice for your brand.

Shipping and Logistics:

- Whether you’re having your clothes manufactured here in the USA or from international vendors, the shipping costs, customs duties, and import/export fees can add substantially to your expenses, and also don’t forget the warehousing costs to store your goods till the time of pick up or sales.

You can check out this Blog for further understanding about USA vs International manufacturers

[USA Vs Overseas Clothing Manufacturers: Full Comparison]

Compliance and Certifications:

- if you brand prioritize ethical sourcing, fair labor practices and specific safety protocols then the Cost associated with relevant certification and compliance will also be factored into your final costs for clothing manufacturing.

There are many aspects that I personally think should not be charged to us, but let’s just say it’s one of those things we have to bear in order to get results. Although it is undesirable, it is also important to run our business.

Strategies for Managing Manufacturing Costs

I hope by now, you have a very clear image of factors that dictate manufacturing cost and how high manufacturing cost can essentially cinch your brand’s neck and make it irrelevant very soon if you do nothing to rectify this.

Private label production cost doesn’t have to be expensive as you can tweak around miscellaneous charges to get yourself a sweet deal, however as being the owner of a profitable business myself, I still encourage you to find a balanced costing to ensure high quality yet affordable production for your brand.

Take a thorough look at the cost-cutting methods mentioned below;

1) Research and Supplier Comparison:

One of the best ways to reduce Cost is by drawing a comparison between 2 suppliers that can provide your brand with a manufacturing solution. But how exactly can you achieve that?

Well, it is fairly easy but time-consuming, so be prepared for a brain workout. You can go around on the internet and different ecommerce platforms to find manufacturers and then ask them questions pertaining to our manufacturing requirements and draw a chart or even a table comparing their rates, delivery, and shipping.

For instance, if you are looking to have your custom hoodies made, then your comparison table would look something like this;

| Category | Manufacturer A | Manufacturer B |

|---|---|---|

| Raw Material | $200 | $170 |

| Production | $90 | $120 |

| Overhead and Shipping | $70 | $60 |

| Total Cost | $360 | $350 |

By looking at the above table , we can safely conclude that manufacturer (B) = 350$ would provide more value as compared to manufacturer(A) = 360$, not just because of cheaper material but also because of their above-average production rate, ensuring a high quality and fair labour production.

Note: your cost comparison table should be in accordance with your brand’s core values.

2) Clear Communication and Detailed Tech Packs:

Yes, communication matters not just in product formulation but also in cost negotiability, if you are clear about your intent and functionality you want your product to serve then it will also be easier for vendors to only opt for specialized raw material and craftsmen for your clothes.

Another noteworthy thing is to have your tech packs as detailed as possible. Think of it like this, if your tech packs are not exact, then most likely you would order a sample and it wouldn’t be up to your standards, so you would repeat the procedure, this cyclic event would add a huge number to your final Cost. So be detailed in communication.

- What are “Tech Packs”?

It is a blueprint that you provide to manufacturers for exact product formulation as you have intended. It includes technical details such as specifications and measurements to create the product.

3) Flexibility in Design and Material Choices:

Finding the sweet spot in manufacturing cost is not entirely dependent on manufacturers; if you want to succeed with your brand, then you have to make compromises on a regular basis.

- For example, you want your sweatshirts to be made from french terry material but the manufacturer you have chosen for the job can not provide french terry in abundance but they offer your a similar feel fabric like loopback jersey material, then as a smart business person you should make such sacrifices if you think your chosen vendors are otherwise perfect for effective costing plan.

- The same goes for immediate designs; if your designs are off by 1 cm or 2 cm, then you can just go over this flaw and do your business.

4) Building Strong Relationships with Manufacturers:

If you believe you have found a reliable manufacturer that offers above-average prices but is exactly what your brand needs, then think of it like an investment. You pay their charges from strong relationships, which opens up the doors for negotiability and an even smoother production process.

Having a relationship in the clothing industry is very important as if there is some trend going on and you want to hop in without having a partner then the chances are, you will be ignored. So, make relationships and patronage with manufacturers.

5) Long-Term Planning and Forecasting:

This can be especially beneficial for those businesses who are in business throughout the entirety of the year, think about this, you noticed a trend of custom printed hoodies to be all time high selling in winter, but you decide to have it manufactured before the season even comes. This will ensure lower pricing than seasonal production.

Remember this one thing: “Wherever there is Demand, there is Supply ,and wherever there is supply, there is high associated costs”.

Conclusion: Making Informed Decisions for Your Clothing Brand

To put everything in perspective, Cost of private label clothing manufacturing depends on several factors, it is not just about raw material and labour associated rather there are also miscellaneous charges one might not even expect!

So as a business owner you should be ready to forecast and even project expected net costings for appropriate pricings of your own clothes to remain profitable, because by now you should probably be aware on why balancing Cost and quality is so important and i believe if you set aside some time and be considerate then you can implement cost management strategies to make informed decisions that align with your brand’s value.

Lastly, it’s your brand’s financial success that matters the most, so you should be ready all the time to even compromise on your end!

Ready to Develop Private Label Clothing Brand?

Partner with us to bring your custom Private Label designs to life! As a trusted private label Clothing Manufacturer, we offer top-quality fabrics, expert craftsmanship, and personalized solutions to match your brand’s style.

Some Frequently Asked Questions

What is a significant factor in private label brand success?

The pricing factor plays a huge role in a brand’s success. Many big players leverage their sales on the premise of quality, but this leaves room for potential budget-conscious consumers.

What unexpected costs should new private label clothing businesses be aware of?

Every new business owner should be aware of extra sampling, defect handling, shipping surprises, and material price changes. If they can navigate these surprises, they can set up affordable manufacturing production.

How can I negotiate better pricing with manufacturers?

One of the best ways to negotiate better pricing is to ask manufacturers for their best and final prices.

How does the complexity of the garment design affect manufacturing costs?

More complex designs require highly skilled labour, specialized materials, and longer production times, which all contribute to a marginal increment in manufacturing costs.