Starting a clothing brand is one of the most exciting journeys any entrepreneur can set sail upon. But taking your unique idea from paper to production can be mind-numbingly challenging. It doesn’t matter whether you are creating a new clothing brand or even starting a new line of products; locating the right manufacturers for your brand’s needs and requirements is necessary for success.

Table of Contents

ToggleBut with so many options, how do you determine which manufacturing service is best for you? How do you even find good apparel manufacturers for startups? And even if you have to find the right partner then how can you develop relationships with them to make a sustainable business tenure?

Answering all of the above questions is the scope of this blog, so stick around and become an honorary expert on clothing manufacturers for new brands and startups.

Clothing Production for Startups

Fashion startups work very closely with manufacturers, in fact it would not be wrong to say it is an absolute necessity to do so!, because of this closure it automatically becomes mandatory for every entrepreneur to understand Clothing production.

If you understand the basics of production then you can navigate around different hurdles and obstacles you will face in the near future while trying to make your brand succeed.

There are many steps that involve the production and associated factors that influence it to such a degree that if you are not careful and attentive enough then it might even bring your brand’s dream to halt.

Reading about all these potential disasters, you must have thought along the lines “Why do I even need to involve myself with manufacturers after placing an order?”, well to answer that. Think about it like this, as a startup owner you are experimenting around and trying different manufacturing services and because of your so little track record, neither you or any brand is pre-equipped with proper knowledge to develop and produce your clothing line-up.

Depending on the needs of your brand, you will need to work with them through the following development stage;

- Fabric sourcing

- Sampling

- Testing

- Costing

Involving yourself in clothing production will ensure a smooth transition of ideas to production.

Finding the Right Manufacturer

There are countless manufacturers who provide different services suited to different manufacturing needs. Some manufacturers offer full in-house production, while others require more thorough involvement from customers, and such makers only provide cutting, making, and trimming.

- Now, how do you decide which one is perfect for your needs? Who is capable and skillful enough to actualize your ideas? Well, the very first thing you have to do is try to align your goals. For example, if you are making a set of custom hoodies that are ethically sourced and made, then it would be in your best interest to find a manufacturer with the same mindset as well.

- After you have decided on the type of manufacturing service you will be needing, your next plausible dilemma has to be about the manufacturers themselves. Many, if not all, entrepreneurs mix up their sourcing from local and international manufacturers, as both have their own sets of advantages and setbacks.

Generally speaking, if you go along with stateside makers, then you can expect high-standard products along with an ethical production process, and if you opt for international vendors, then you can find shockingly low prices and high standards of streamlined processes.

If you are interested in finding more about USA vs International manufacturers, then you can check out this blog : [USA Vs Overseas Clothing Manufacturers: Full Comparison]

It is absolutely recommended to take some time and research manufacturers and their business policies before deciding upon a “Right Manufacturer”. You can take a thorough look at below mentioned points to make a right decision.

Ready to Develop Private Label Brand?

Partner with us to bring your custom Private Label designs to life! As a trusted Private Label Clothing Manufacturer, we offer top-quality fabrics, expert craftsmanship, and personalized solutions to match your brand’s style.

Area of Expertise:

- A particular specialism of vendors can ensure timely and exact delivery of goods without charging extra or taking longer than usual in order to source material and specific labour. For example, if you want to have custom activewear, then you should go for a brand that mostly, if not occasionally, does business in that category.

Client’s Testimonials:

- Searching for previous customers and what they have to say about manufacturers will help you understand their business model and see if they even align with your vision and values.

Business Credentials:

Search and see if your potential manufacturers have any certifications or meet the compliance and auditing requirements to meet your demands. checking their lead times, MOQs and payment terms also determines if you can forge a good working relationship with them or not.

The Ultimate Factor – Budget:

Your right manufacturer should have balanced out levels of product quality and potential price margins. Suppose your potential manufacturer can only provide one of the following values; then, with absolute certainty, they are not for you because, as a new player in the market, you need a maker that can compromise for you and try to provide value for your brand.

- As a matter of fact, we have devised a table that explains how even the right manufacturer becomes unsuitable for you if your budget is not aligned with their demands.

You can, in fact, use the quotation data you may have gotten from different manufacturers and put it in the table below yourself to see how much benefit you will gain from patronage.

| Aspect | Expensive – Fully Capable | Affordable – Less Capable |

|---|---|---|

| Development Cost | $300 for 50 sweatshirts | $150 for 50 sweatshirts |

| Production Cost | $800 for 50 sweatshirts | $500 for 50 sweatshirts |

| Net Cost | $1100 before Freight and Custom taxes | $650 before Freight and Custom taxes |

| Market Pricing | Typical price: $25 – $35 per sweatshirt | Typical price: $10 – $15 per sweatshirt |

| Assumed Sales Revenue | 50 x $35 = $1750 | 50 x $15 = $750 |

| Profit | $1750 – $1100 = $650 (16.7% profit) | $750 – $650 = $100 (34.8% profit) |

There are many other factors that influence the immediate pricings of clothes but according to the table, if there is a decent market for normal quality sweatshirts then investing in Affordable – Less Capable manufacturers yields double the profits than going with Expensive – Fully Capable.

The thing is, as a business owner you need to make continuous settlements but if you manage to find a sweet balance between these 2 worlds then you can expand your brand in no time.

You can even ask some of these following questions to see if they can truly meet your standards and goal;

- Have you ever worked with a similar clothing order?

- Do you offer trade insurances?

- Can you provide your Certifications and compliances?

- Are there any additional fees or charges I should be aware of?

- Do you follow Confidentiality and non-disclosure policies?

- If you are facing troubles finding such vendors then we highly recommend this clothing manufacturers for new brands, as they not only provide high quality clothes but also with affordable prices and MOQs.

[https://www.privatelabelclothingmanufacturers.com/]

Conducting meticulous research and verification of these factors will enable you to effectively narrow down options and allow for the final selection of the right manufacturing partner. However if you have extra time on your hands then you can check the following five questions you should ask every potential manufacturing partner of your brand!

.Navigating the Development Stage

You finally found the right manufacturer for your brand, but now what? If you are thinking that you can represent your idea to the manufacturer and they can make it come alive, then you would be wrong on so many levels.

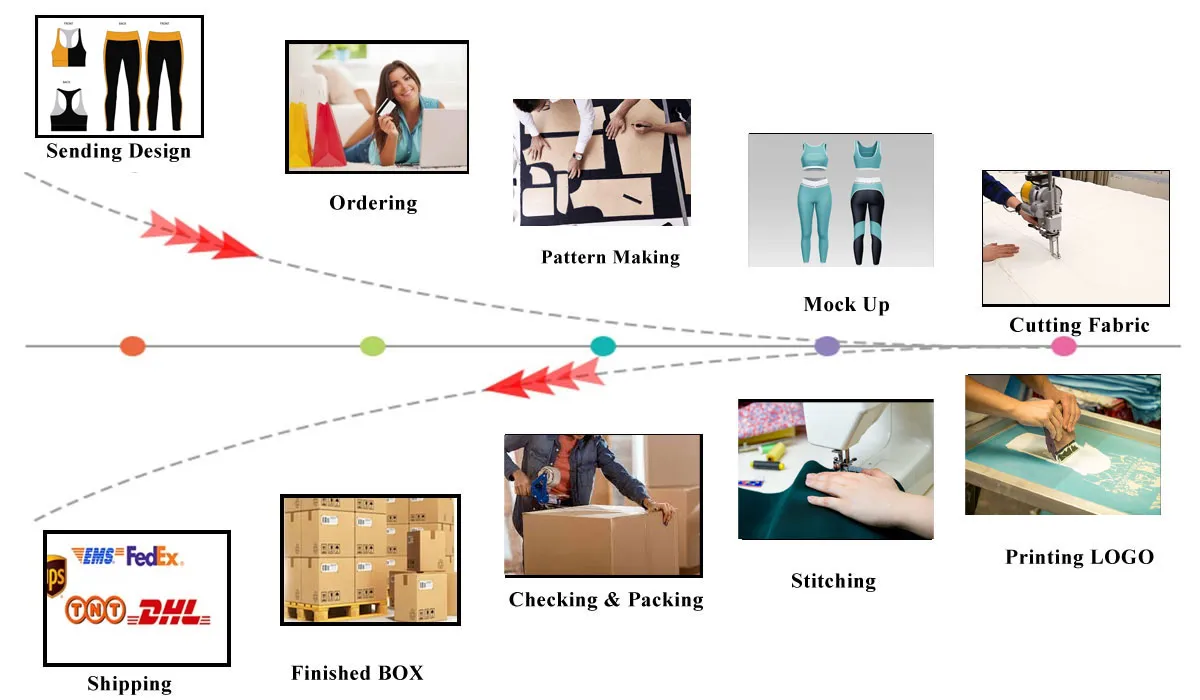

Full-on production is only possible when every necessary foundational work has been laid, such as finalizing the design, material sourcing, patterning, and many more. Before production, comes the development stage and this is where your designs are actualized into physical form.

Having a clear communication and attention to detail are key steps for proper development of your goods. Below are some of the factors that directly influence this phase;

Importance of Tech Packs:

- A tech pack is basically a comprehensive document that outlines every possible detail of your intended garment, including measurements, the type of material, the method best suited for construction, and even a labelling guide. A well-prepared tech pack minimizes errors and ensures manufacturers understand your vision.

Sampling and Refinement:

- It’s a crucial phase for a streamlined and quality production. Sampling ensures iterative refinement required to translate your vision flawlessly. It begins with prototyping, a physical interpretation of your design; these early samples allow for early assessment of the overall quality in order to make fundamental adjustments.

After prototyping has been finalized, the focus shifts to fit samples. These samples are all about achieving precise sizing and drape of clothes. Throughout the process, you can expect several rounds of samples as you try to find the perfect measurements and silhouette of your clothes.

At the last step of sampling, there is something called a pre-production sample, or PPS. This sample serves as the ultimate benchmark that represents the exact quality for your bulk production, and by allowing for these continuous sample iterations, you gain a significant opportunity to identify and rectify any issues before full production, ultimately saving your time and funds.

Proper Communication:

Don’t assume your manufacturer is a mind reader and can understand your envisioned clothes easily; you have to spend a lot of time trying to make them understand your needs.

Try to be explicit in your communication and provide a detailed feedback on samples, ranging from how does clothes feel to overall appeal using simple and straightforward language, and perhaps the most important thing is iterative questioning from your side, as asking them about problems can also push them to provide you for better alternative and solution for your manufacturing needs.

Importance of IPOs:

- IPOs or Intellectual Property Rights are legal protections granted to designers of original works of authorship, inventions, trademarks, and trade secrets, allowing them to control the use and distribution of their creations.

And understanding basic copyright principles can help you protect your designs from theft and leakage. It is highly advisable to consider a non-disclosure agreement with your manufacturers to keep your ideas confidential and secure.

The developmental stage is not as straightforward as you might think. There are many hurdles and setbacks, this is why you should put utmost care and thought into it and watch out for things that might hinder proper development of your clothes such as vague tech packs.

Rushing the sampling process and not providing timely and valuable feedback to the manufacturer as instead of saving money, it can cost you almost double or perhaps triple the amount you otherwise would have spended for development.

Understanding the Clothing Manufacturing Process For Startups

After your clothes developmental stage has been successfully completed and pre-production samples are approved, your design shifts to bulk or full production process. This is the stage where most of your capital will be utilized, and ensuring quality throughout is not just on manufacture but also your responsibility as well.

Understanding the complexities of this process is absolutely crucial for managing timelines and the timely delivery of your goods. A typical manufacturing process has several key steps that every high-quality manufacturer should follow:

- Minimum Order Quantities(MOQs): Most, if not all, manufacturers operate with MOQs, which basically means the smallest order number they are willing to produce, and MOQs are decided by manufacturers based on the complexity of the garments for clothes fabricating, the material involved, along with the manufacturer’s business model as well.

Understanding and aligning with a manufacturer’s MOQS is significant for your initial production planning and inventory management.

Lead Times:

This terminology refers to the total time required from the placement of order to point at which goods are ready for shipment. These lead times can severely fluctuate depending on the manufacturer’s schedule, the complexity of your clothing designs, and even material availability. Accurate lead time forecasting is essential for efficient business planning, including marketing and sales strategy.

Quality Control:

Implementing robust quality control practices is essential for standardized quality of clothes. This procedure begins with the inspection of raw material and goes through the process inspection and ends with final QC before garments are packaged and shipped. Establishing a clear quality standard and conveying these expectations to your selected vendor is crucial for high-quality clothes.

Labelling and Packaging:

The details of labelling, such as brand labels, size tags, and packaging, such as boxes and bags, contribute significantly to a brand’s presentation and customer experience. Although you can do it yourself once the goods have arrived, if you’re going with a complete production manufacturer, then be attentive to their alignment with the brand’s identity and regulatory requirements.

Freight and Logistics:

Planning for a cost-effective shipping for your clothes is a critical final step in the production process. Consider factors such as transportation cost, import/export fees, and customs clearance procedures for a smooth transition from the manufacturing factory to your inventory or warehouse.

Timely shipping from manufacturers means timely delivery of clothes to your customers.

There are many variable factors that might affect the production process, but you would only know them if you are communicating with your manufacturer in a timely manner; this is why “Communication” is continuously highlighted in this blog.

Building Strong Relationships with Manufacturers

Your partnership with the manufacturer doesn’t end after production ends; rather, it’s only a beginning, and it is highly encouraged never to be shy about further communication. Inquiring about different product line-ups and giving constructive feedback will develop a healthy working relationship between you and your manufacturer.

Having great relations will ensure a world of business opportunities, such as leeway for negotiability in prices and MOQs, and even the requirement of specific labour or skill. This all will help you expand your borders and ensure the healthy expansion of your business.

If you are not sure how to start building goodwill with your manufacturer, then read through the following points mentioned below;

Treat Your Manufacturers Like Partners:

- One way to treat your clothing manufacturers like partners is through effective communication. Keeping them updated on business changes helps them adjust their manufacturing workflow accordingly, which will mean less hassle on their end.

Pay-on-Time:

Maintaining a positive reputation is a significant concern of every manufacturer because they are there to make money as well. One of the most critical steps in cultivating a better Brand-Manufacturer relationship is ensuring timely payments according to agreed terms.

Visit Their Factories:

Visiting their manufacturing unit can provide valuable insights into their operations and can help you build a more personal connection. It shows your commitment and allows face-to-face discussions.

Be Reasonable in Negotiations:

Although it is crucial to negotiate pricing and terms for your brand’s success, try to aim for a fair agreement that can benefit both parties. Trying to negotiate too hard can negatively impact your relationship and even the quality of your clothes.

Showing Appreciation:

A simple acknowledgment of your manufacturer’s hard work can go a long way in building goodwill, think of it as tipping. Even though you have paid for your goods but still a simple thank you wouldnt hurt anyone.

Why Is a Good Partnership Crucial for a Clothing Startup?

A reliable and cooperative manufacturing partner is more than just a service provider for your brand. They are an integral component of your supply chain and a direct influencer on the quality, consistency, and success of your clothing line. Maintaining and even nurturing this relationship is a mandatory act for any aspiring fashion startup to thrive and succeed.

Conclusion

Navigating through the world of clothing manufacturers as a startup demands careful attention to details and strategic partnerships and by thorough research and clear communication with your potential manufacturer you can effectively transform your design aspirations into actual clothes.

However remember that developing and maintaining relationships is the ultimate key to success: as it will pave the path for smoother production process and stronger foundation of your brand. One other noteworthy tip is to maintain a meticulous approach to each step, from sourcing to production.

This will empower your startup to not only create high-quality products but also build a sustainable presence in the fashion industry, and with the right knowledge and partners, your envisioned designs could change the whole clothing industry!

FAQs About Clothing Manufacturers

1) What are typical MOQs in the clothing industry?

MOQs can vary significantly as they directly depend on the manufacturer. For example, a high-capacity manufacturer will have 500-1000 minimum order quantities, and low-capacity manufacturers might have 100-200 minimum order quantities.

2) Why are low MOQs considered significant for new business?

Having low MOQs can be beneficial in several ways. It requires a low initial investment and less risk of overstocking, which essentially allows endless business opportunities.

3) How do I calculate what MOQ I can realistically handle?

To calculate your optimum MOQs realistically, consider your budget, storage capacity, projected sales, and risks associated with unsold inventory.